Renault Group

Tech Industry

Days

#PassionIndustry

An invitation to discover how Renault Group visualizes and synchronizes the operation of all its factories and its supply chain in real time: the encounter between the physical and the virtual world to improve performance!

In an environment that is becoming more complex by the day, the global reading offered by the Metaverse has many benefits, such as better visibility and a way to understand faster and therefore anticipate.

Supervision of our operations allows us to act in the right place and in real time, thus reducing costs and increasing the quality of our production system and supply chain. This supervision also means prevention and agility in order to adapt to unforeseen events or hazards.

Similarly, this supervision is key in our approach to decarbonizing our sites and reducing our energy consumption.

Convergence of technologies, openness to digital technology at the service of people, the virtues of the Metaverse are demonstrated in this exhibition by concrete examples.

1.1 The industrial data platform developed by Renault Group:

IDM4.0

Renault Group has developed an in-house platform, IDM4.0 (Industrial Data Management

Platform

4.0), which opens the door to the collect of all of our industrial data. This solution for

collecting and standardizing data allows us to control our processes and restore data from

our

industrial equipment on a standard basis and on a large scale.

Stored in the Cloud (Google Cloud), this data feeds the industrial Metaverse, and

allows us to correct or improve our production process in real time.

Today, more than 70% of our industrial equipment is connected.

The supervision of our equipment has allowed, for example, since 2019, a detection of 300

alerts

and the avoidance of production stoppages.

1.2 The ID@Scale industrial data platform: our partnership with

Atos

Renault Group value-generating industrial data acquisition solution is also benefiting other

companies. Our solution is marketed through our partnership with Atos.

Named ID@Scale, ATOS commercializes it and supports companies in their digital

transformation.

2.1 Artificial intelligence to serve production teams

AI makes life easier for operators in their daily tasks and allows production actors to

focus on

higher value-added tasks. AI applications are user-centered and help decision making.

2.2 AI for remote vision control

Thanks to a partnership between Google Cloud and Renault Group in AI, an image data

management

platform has been developed. This platform simplifies vision control. Example of

application:

the Pokaiok wheel concept, developed in collaboration with Buwaei, which allows to ensure

the

regulatory traceability of tires with efficiency and at lower costs.

2.3 Remote vision control

The Cobot function, developed by Renault Group, allows the autonomous operation of a robot

coupled with AI. With a collaborative gripper and a camera function, it automates the

control of

parts and facilitates the work of the operator. The validation of the conformity of the

parts

can thus be done without handling.

2.4 DWS: the operator tablet

The Digital Work Station (DWS) provides the operator with all the information needed for his

workstation and allows him to make requests in real time to his production supervisor.

2.5 CHUET: the production supervisor tablet

The production supervisor tablet (CHUET) allows him to visualize all the events in real

time. He

can thus make the right decisions while remaining close to his work environment.

2.6 Virtual training

Virtual training is an application that allows the link between the mission statement and

the

right operating gestures on video.

2.7 Self Service Big Data for plant users

Self-Service Big Data is an analysis environment on Google Cloud Platform. It collects all

the

product and process analysis data and their context. Thanks to Google Cloud Looker

technology,

the

manager can format them in an intuitive way and analyze them to make the right decisions.

2.8 Renault Virtual Twin (RVT)

RVT is a collaborative backbone enabling to share all product and service data throughout

their

life cycle. It is a unique reference for all the company's businesses.

In the digital continuity of the product, producing a complete digital twin of design,

validation, training and performance is key for every actor involved with the Group.

2.9 Virtual reality in production engineering

The simulations made possible by virtual reality in the industrial digital twin make an

important contribution to industrial performance. They are carried out before the launch of

production tools.

Example of application: study of picking-kitting zones for the validation of ergonomic

conditions.

2.10 Virtual reality in training activities

Immersed in virtual reality, our attention and emotional involvement are four times greater

than

in a traditional training course.

These trainings are quick to deploy and economical in terms of materials and resources.

3.1 Alpine: additive manufacturing for a brand at the cutting edge of

performance

The Alpine brand innovates and offers design parts for small series.

3.2 Inventing industrial additive manufacturing

Renault Group is a member of the HUB 3D Print consortium and, with its partners, is pushing back

the limits of polymer additive manufacturing.

3.3 Polymer additive manufacturing at Flins Refactory

The Flins site has a Polymer Additive Manufacturing center and produces prototypes, tools and

vehicle parts on demand.

3.4 Additive manufacturing for plants efficiency

From tooling production to machine maintenance, the 3D printing centers on the manufacturing

sites respond fastly to manufacturing needs and enable cost and storage reduction.

4.1 Renault Group, pioneer in E-Powertrain manufacturing

Manufacturing of EESM (Electric Excited Synchronous Machine) motors since 2015, motors with

wound rotor

The engines of the future

The support for Cléon team reskilling.

4.4 Renault Group develops a battery with Verkor

Renault Group is working with Verkor to develop and industrialize a battery module for mass

production from 2025.

5.1 Numerical simulation of Body in White accuracy

Today, Autoform software simulates the feasibility of stamping and hemming processes. In the

future, the simulation of the geometry of parts resulting from stamping, assembly and hemming

will make it possible to define compensations on the processes and achieve conformity faster

(e.g.: reduction of adjustment loops on an aluminum hood).

5.2 "Micro-factory spirit", ultra-flexible process

The use of cooperative robots with interchangeable grippers makes it possible to create a

flexible assembly station without jig on the ground.

Among the gains, the optimization of the surface and the investments.

5.3 Thermoplastic tailgate by water injection

Weight is a key driver of vehicle performance. Water injection brings a technological

breakthrough in the design of plastic part. The injection of water creates a hollow rigid body.

It allows, compared to the previous generation of thermoplastic tailgate: a weight gain of 20%,

a saving of 30€ / vehicle.

This patented innovation was developed by Renault Group.

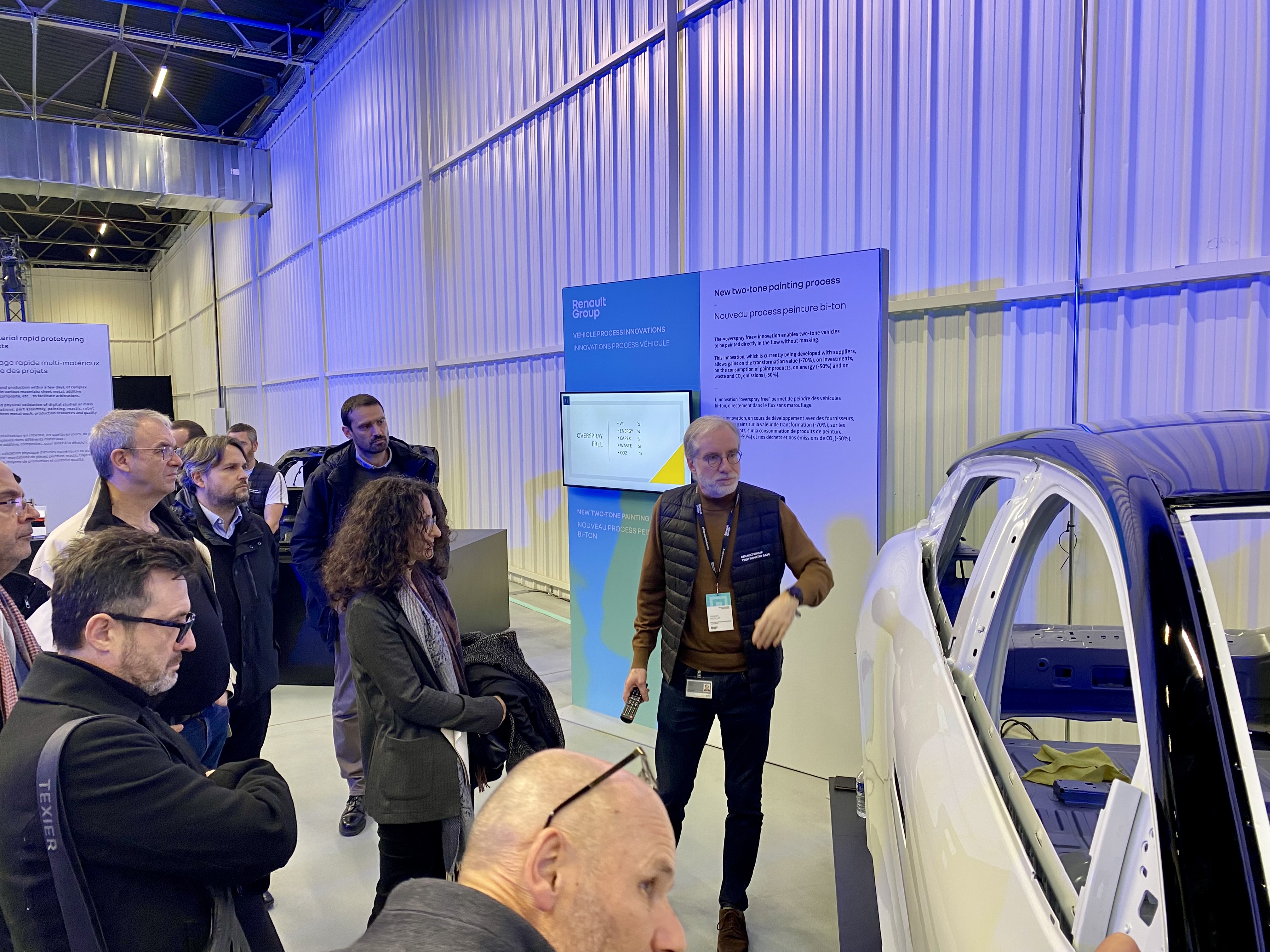

5.4 New two-tone paint process

The "overspray free" innovation makes it possible to paint two-tone vehicles directly in the

manufacturing flow without "marouflage", an operation that consists of camouflaging the part

that is not to be painted. This innovation, which is currently being developed with suppliers,

allows for savings in investments, consumption of paint products, energy (-50%) and reduces our

waste and CO2 emissions (-50%).

5.5 Multi-material rapid prototyping for projects

Thanks to in-house design and production, complex prototype parts are produced in a few days in

different materials: sheet metal, additive manufacturing, composite, etc., to help projects make

the right decision.

6.2 Control Tower of the Extended Supply Chain

The Control Tower is the point of convergence of the Supply Chain professions in a dedicated

space: the Control Room. As a global supervision tool and information flow concentrator, it

alerts in real time of risks or anomalies on all our transports and proposes optimized

crisis

management scenarios thanks to AI.

6.3 Tracking Telematics: an asset for customer satisfaction

Renault Group is one of the very first car manufacturers to collect massive amounts of data

from

its vehicles during transport. The "health" data collected (battery status, tires, etc.)

contributes to maintaining the highest level of quality during transport to the customer.

The analysis of GPS positions at key moments of the transport, with the triggering of

possible

corrective actions, contribute to guarantee the promised delivery date, a major criterion of

our

customers' satisfaction.

7.1 Decarbonization of industry: a lever for energy

independence

Renault Group is committed to becoming Net Zero Carbon by 2025 for the ElectriCity division

and

the Cléon plant, by 2030 for manufacturing sites in Europe, and by 2050 for all industrial

facilities worldwide. The Group has embarked on a very ambitious plan to decarbonize and

make

its industry energy independent, with the aim of achieving a 50% renewable energy mix in

France

by 2026 and 100% by 2030.

7.2 ECOGY energy portal, a key element in energy efficiency

In 2022, Renault Group will migrate its energy portal to a more agile and connected solution

on

the Google Cloud Platform. An ambitious plan to deploy connected energy meters will enable

precise monitoring of consumption at the level of a manufacturing plant.

7.3 Real-time consumption: everyone involved in energy

savings

In order to accelerate collective awareness and optimize energy consumption (residual

consumption when the plant is shut down), instantaneous consumption data (gas and

electricity)

is made available to the company's operational players.